The latest release of TMS is now available

Four big improvements have been implemented in our Technical Monitoring System in the latest months. In particular:

DCMA Quality Report is now available also for MS Project

No TMS Project is required, just XML Files exported from MS Project.

If your Sub Contractor is using MS Project, you can check and evaluate its Schedule Quality in a few seconds.

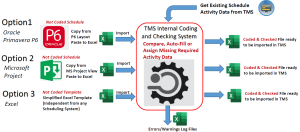

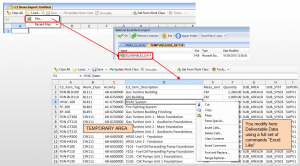

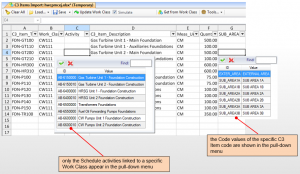

Internal Coding & Checking System for Schedule Activities

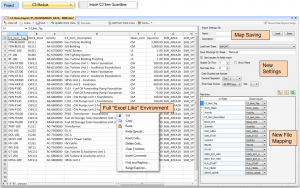

Now you can codify your schedule Activities and assign Weight Parameters directly in TMS.

No TMS Main WS Codes, No User Defined Fields are required in your Scheduling System (P6 or MS Project).

Code Assignments are facilitated by TMS in an “Excel-like environment” and achieved from the contextual pull down.

Internal Coding can be used with files coming from P6, from MS Project or from Generic Simplified Excel Files (independent from any Scheduling System).

Sanity checks are also performed in order to ensure that the Schedule Data that will be imported in TMS are “Error free”.

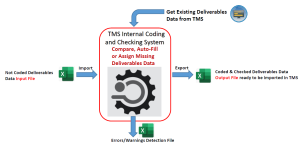

Internal Coding & Checking System for Deliverables

Now you can codify your Deliverables in a facilitated “Excel-like Environment” before importing them in TMS or in your Document Control System.

All the Deliverables Code Assignment are facilitated by TMS and achieved from the contextual pull down.

Sanity checks are also performed in order to ensure that the Deliverable Data that will be imported in TMS are “Error free”.

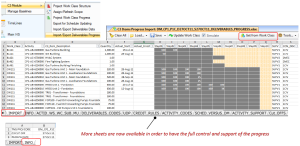

We have added new useful info in “Export Deliverables Progress”

In particular we have added new sheets in the generated workbook:

- Credit Rules

- Activity Codes

- Schedule VS Deliverables Module (Comparison at Activity Level between Actual Schedule Data from P6 and Actual Deliverable Data from TMS)

- Activity Progress Support (Each Schedule Activity Progress supported by Deliverables Status)

Get the full list of new features and implementations from our support portal, by downloading the latest documentation.

IOGP standard association, Sketch revision synchronization and much more

A new Puma5 release has just been made available. This is what you can find in the latest Puma5 version No. 02.950.04.00:

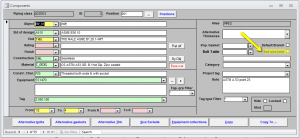

Material category

The ‘Material category’ has been added to associate the IOGP standard to the material codes used for component definition. Of course, this new attribute can be used also for other definitions than the IOGP standard. Using the ‘material category’ is optional. The following modifications have been applied:

- the ‘material category’ dictionary has been added: item menu ‘General/Types/ Material Category;

- the ‘material category’ field has been added in the ‘General\Dictionaries\Material’ form; here a link can be created between the two attributes (option);

- the ‘material category’ field has been added in the ‘piping class header’ form; here it can be declared which ‘material category’ the piping class shall be associated with (option);

- the ‘mat cat’ control has been added in the ‘piping class components’ form: it narrows the material code list down to the codes associated with the ‘material category’ code set the in ‘piping class’ header;

- ‘Piping class check’ function: the warning No. 687 “Piping class components detail: Material not coherent with piping class header material category” has been added;

- Piping class print: the ‘material category’ field has been added in the horizontal vertical ‘piping class’ reports.

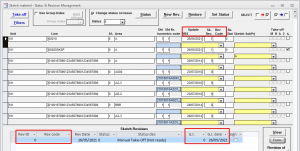

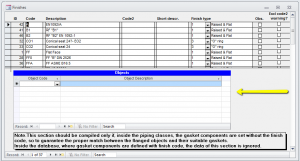

Sketch revision synchronization

It is now possible to synchronize the sketch revisions between two different managements: ‘Isometric Sketch list’ (= type “A”) and ‘Sketch material – Status & Revision management’ (= type “B”). Type “A” is the management that has always been inside the application, with a ‘Sketch revision indexes’ dictionary that contains the ‘revision index’ code, the date, the description and information relating to the staff who performed the issue. Type “B” is the management which was added to the application a few years ago and it also allows the archiving of the take-off by associating them with revision codes. Thanks to the synchronization of sketch revisions the management indexes of type “B” are copied to the management indexes of type “A” so that:

- it is no longer necessary to issue the sketches through the two different functions;

- “A” type reviews can be used for the reports of the ‘Sketch material list’;

- “A” type revisions can be used in the export function to Cosmo5.

A full description of the new functions is available for download from our support portal.

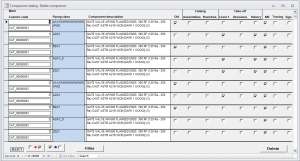

Component catalog delete OLD component

The ‘Component catalog delete OLD component’ function has been added. With this function it is possible to delete components that do not comply with the piping class any more (“OLD”). The cancellation deletes the component for the piping class and any links to the “Bolts linked components” and “Gasket linked component” tables, and the entries in the “upgrade operation log” table. Regardless of the filter applied, the component selection – and therefore its cancellation – can only take place for components of “OLD” type and with no reference in the following tables: Assemblies, Branches, Take-off level 1, Take-off revisions, Take-off history, Material requisition, Tracing. After deleting the components of “OLD” type for the relevant piping classes, it is also possible to delete any components that are not referred to any piping class: to do this, use the ‘Filter’ form to set the filter option ‘Piping class = No’.

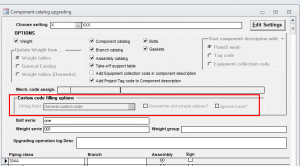

Update project custom code with custom code taken from general catalog

The ‘General custom code’ item has been added in the selection box of the ‘Custom code filling options’ field (settings); this option refers to the values of the ‘custom code’ field of the ‘general catalog’ table. The options ‘Overwrite not empty values’ and ‘Ignore lock’ are also available for use in this field.

For a complete overview of the new features added in the latest version of Puma5, please log into our support portal and download the latest “what’s new” document stored in the Puma5 section.

New features for Alternative Thickness and Composer

The latest version of Puma5 application (02.950.02.00.) shows some important modifications applied to the Alternative Thickness management and to the Composer table structure.

Alternative thickness management – Previously, the function of copying piping classes between different projects did not transfer the link between the piping classes and the ‘alternative thickness’ table code; this resulted in the loss of the thickness settings of some components of the piping class, such as, for example, ”Nipple” type objects.

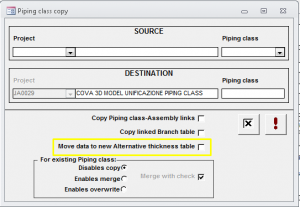

Now the ‘Piping class copy’ form has a new option named ‘Move data to new Alternative thickness table’;

when the option is enabled, the thickness measurements of the Alternative thickness table linked to the component get appended to the new ‘Alternative thickness’ section of the same component.

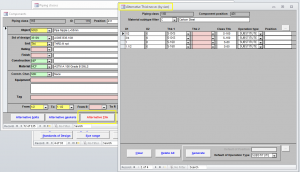

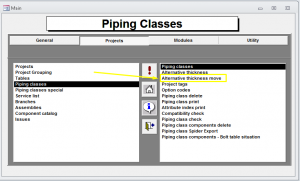

The ‘Piping classes’ menu also introduces another new feature: ‘Alternative thickness move’.

This new function “moves” the thickness measurements from the “alternative thickness” table associated with the component, into the “Piping class component – Alternative thickness” section of the component itself. The code of the previous ‘Alternative thickness’ table will be removed from the definition of the piping class component.

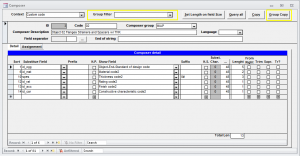

Composer – it is now possible to create more than one set of assignment rules for the same ‘Composer context’ code. Therefore different groups of rules can be used on different projects and it will be possible to repeat in a ‘composer group’ the same ‘assignments’ already present in another group.

The table structure has changed. Two keys now identify records:

- the main unique index remains composed of the ’Composer ID’ field only;

- the unique secondary index, previously composed of the ‘Composer code’ field only, is now composed of the ‘Composer group ID’ + ‘Composer code’ fields.

The ‘composer group’ field is now mandatory. The procedure that updates the application to this version introduces a value in the ‘composer group’ field, in case this field is empty. The new ‘composer group code’ values are automatically generated through the text “SysGrp” followed by a progressive number, for example “SysGrp0006”.

A new type of report has been created in the Take-Off module of Puma5: it is called “BILL OF MATERIAL LIST (3) Export only” and it produces an ‘output’ which is almost equal to the report called “BILL OF MATERIAL LIST (1)”. The main differences are:

- no report is generated and the data is exported to a file (Microsoft Access, Microsoft Excel format);

- not all the fields that are exported with the “BILL OF MATERIAL LIST (1)” report are present;

- the ‘List of piping class’ field has been added which lists, separated by a comma, the codes of the piping classes to which the component belongs.

For a complete overview of the new features of this Puma5 release, please log into our support portal and download the latest documentation.

Puma5 upgrades to version 2.95

WARNING: this new release upgrades Puma5 from any version to 2.95; to avoid any problems during the installation, please make sure that you ask for the new database license by opening a ticket on our support portal before running the upgrade (http://support.cla-it.com/).

Two main improvements have been made to the automatisms generating the component catalogue:

bolts and gaskets generation on the second diameter of a component – you can enable the function through the ‘2nd size joint’ field in the ‘Components’ section of the ‘Piping class’ form (this field is active only for those components having the bolts and gaskets generation enabled). During the ‘Component catalog upgrading’ procedure, for those components having the ‘2nd size joint’ indicator activated, bolts and gaskets will be generated by using the second diameter value (branch);

new ‘Object-Finish’ table in the Object-Finish dictionary – the table has been added to allow the creation of links between gasket-type objects and the ‘finish’ attribute. These links are used only for those gasket-type components that are defined without the ‘finish’ code in the piping classes.

During the ‘Component catalog upgrading’ procedure, for gaskets with no ‘finish’ code, a link is created with the flanged objects by using the ‘finish’ code of the ‘object-finish’ dictionary.

Other improvements refer to the general environment:

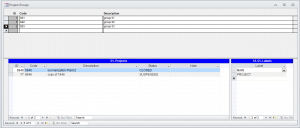

project grouping functions – in order to manage the grouping of different projects, new functions have been added. These functions allow the creation of links between different projects of the same database (read the “what’s new” document available for download from the support portal for more details);

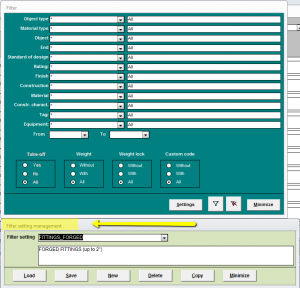

filter setting – the ‘filter setting’ management has been added; it is now possible to save all filter fields values of a form into the database. This new function is described in the document named WHAT’S_NEW_PUMA5_02.950.00.00_Detail_EN.pdf, available for download from the support portal.

New reports and new import/export options in TMS

Many implementations have been under way since the last newsletter. Here is a quick recap of some of the new features added to our Technical Monitoring System in the latest months.

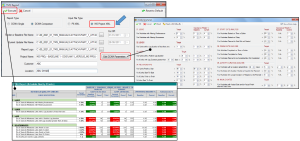

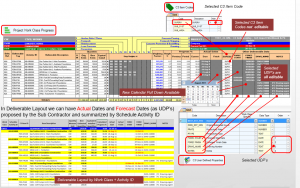

Project Work Class Progress – User-Defined Properties are now editable directly on the screen or on the exported Workbook (selected values only).

The Deliverable layout shows the Actual Dates and Forecast Dates (as UDP’s) proposed by the Subcontractor and summarized by Schedule Activity ID.

Exporting the Workbook – The Excel Workbook can now be exported by selecting one out of two options:

- For Progress, Actual Dates UDP Values Import – the exported Workbook is fully protected except for the Data Entry Area, that includes Progress by Step, Actual Dates and UDP’s;

- Unprotected Workbook (cannot be imported) – the exported Workbook is fully unprotected (for External Use) and cannot be re-imported in TMS.

When exporting the Workbook for data entry, one process can now handle several subcontractors files at a time and the same happens for the import procedure, too. To avoid misunderstanding, the Current Cut off Date is now empty by default; the Subcontractor will indicate the Current Cut off Date in the Summary Sheet and the same date will be propagated automatically in all sheets.

Importing the Workbook – In case the import of Workbook Deliverables shows items that are not exactly matching with TMS Deliverables, a warning message will appear and User will be able to review an Excel file with two sheets, “Not existing in TMS” and “Not existing in Workbook”.

New Import of Schedule Data with simplified Excel Templates – This new import procedure will let you take advantage of:

- being independent from any scheduling system

- maximized Import/Export of Excel files only

- easy creation with minimal data

- full control of your Subcontractors with Deliverable Module

- all TMS features available like in XML Import

- all TMS reports available.

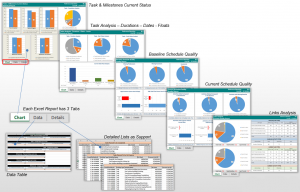

New Statistical & Quality Reports – many new reports are ready for use! For a comprehensive overview of what is available, log into our support portal and download the latest documentation.

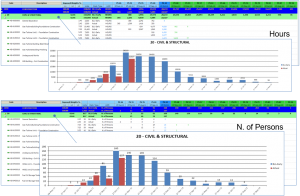

Progress view – It is now possible to generate any kind of user-defined Alternative Progress View based on Units (i.e Hours) imported from P6. You can have “Instant Charts” at any level – from Top Level up to Activity Level – of your Alternative Structure; “Instant Charts” can be generated with any kind of user-defined Progress View and can be saved in Excel.

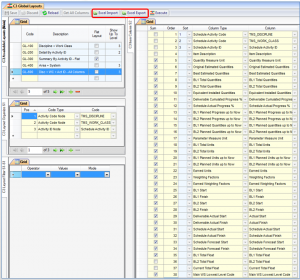

C3 Global Layouts – There are new Deliverable Layout Specs, where User can:

- compose the hierarchy of the layout

- apply filters

- select columns to be represented

- define columns order and sorting

- flag column that needs totals

- edit column headers

- summarize layout at specific level.

Layout Specs are saved and they can be exported from one project and imported into another project. New selectable columns related to the Scheduling Data (Planned, Actual and Forecast) have been added and they can be compared with the Actual results obtained from the Detailed Deliverables Status.

Get the full list of new features and implementations from our support portal, by downloading the latest documentation.

New features of Puma5 latest release (02.910.07.01)

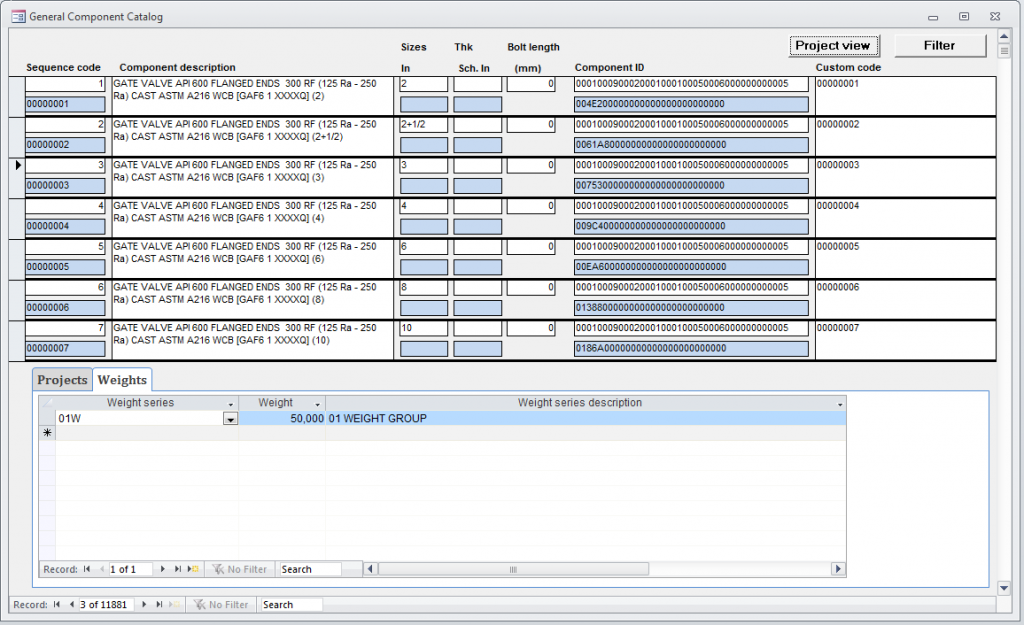

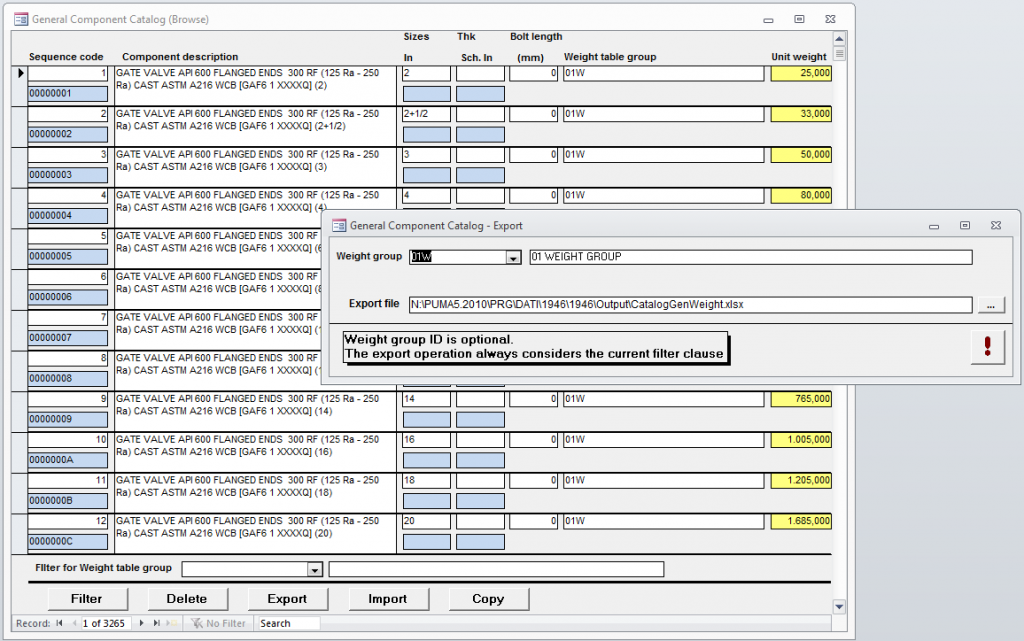

Component weight on General Catalog – A new major feature has been added: the component weight is now available in the general catalog.

Previously, the component weight was stored for the specific project only; now it is possible to add component weights that are ready to be used for any project inserted in Puma5.

Weights for the single component are divided into weight groups, and for each one of these groups a dictionary has been added.

Data flow between the General Catalog and the component catalog of the single project is bidirectional: values of the project component catalog can populate the General Catalog or the weight values of the General Catalog can be inserted into the project component catalog.

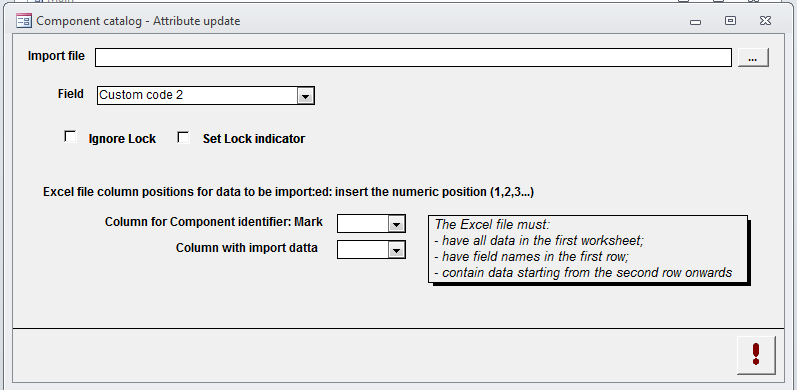

Update of the component catalog attributes – Speaking of the project component catalog, there is a new function that allows the update of some fields by using a two-column Excel file; the file needs only one column with the component ID (=mark) and one column with the value to be updated.

The function is restricted to the following fields:

- Component custom description

- Component custom description 2

- Component custom description 3

- Component custom description 4

- Component custom description 5

- Custom code

- Custom code 2

- Custom code 3

- Custom code 4

- Custom code 5

- User Component Description

- Weight.

More detailed information can be found in the “What’s new” document available for download by logging into our support portal

TMS – November 2018 release

TMS has reached the release No. 01.001.03.07: let us introduce you to the big improvements of this latest release.

Following the feedback received from TMS users, we have focused in particular on the Deliverables management. The import/export of Deliverables data has been maximized with new powerful features and innovative approaches to simplify and speed up the process and to eliminate some existing bottlenecks.

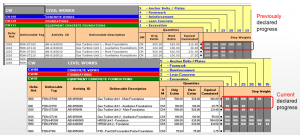

Import of the Workbook filled by the Sub Contractor

When importing the workbook, it is now possible to detect if the progress of a given step of a given deliverable is lower than the one previously declared; a report can be generated (and saved in Excel) showing deliverables with Current Progress by step less than the previous declared progress.

The Import form of Deliverables data has a new User Interface:

Import of Deliverables Data – New Approach

Different options are available for the Deliverables data import: with option 1, User can load an Excel file (provided, for example, by Engineering) and partially or totally recover some Deliverable Data from it.

With option 2, it is possible to get existing Deliverables by using the “Get from Work Class” command and add/delete/modify Deliverable Data.

Automatic filling-in of missing information

If the Deliverables data have missing information and this information already exists in TMS, it can be automatically retrieved by using the “Auto Fill > All Linked Properties” command. Thanks to a pull-down menu available for each specific context, data can be inserted as shown in the screenshot below.

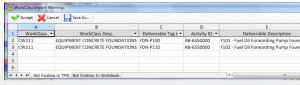

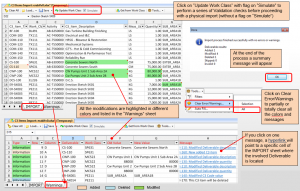

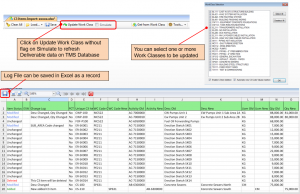

Validation checks performed by TMS

Before actually importing a Work Class, User can perform validation checks and simulate the importing process to double-check whether there are any errors.

Messages displayed can be sorted by errors, info, warnings.

Once the simulation returns no errors, the Work Class can be imported, as per instructions below.

More detailed information about TMS latest release are available by logging into our support portal at https://cla.freshdesk.com/support/home

Puma5 release No. 02.910.06.00 – what’s new?

Actually, there are a few nice new features you will be interested in. Let’s start with the Piping Class module and with a new procedure taking place at the end of the mechanical check of internal thicknesses. Up to now, you would end the process and get a report showing which thicknesses are suitable and which are not. Starting from this release – if you choose to – at the end of the check procedure, a form will be displayed allowing User to modify the unsuitable thicknesses.

Puma5 version 2.91 patch 5 now available

The version 2.91 patch 5 (02.910.05.00) of our Puma5 software brings some big news to the Piping Class and the Mechanical Checks modules.

As usual, you will find the complete details in the What’s New document available for download from our Customer Care portal, however we give you here a glimpse of what you will find in Puma5 latest release.

Piping Class module – Piping Class form

There is a new ‘Copy’ button here and it is used to copy thickness tables among different classes belonging to the project in use (note: this can be done only among piping classes, whose associated ‘base material’ belongs to the same ‘Material subtypes (S2)’ section of the thickness dictionary).